System Palette

Epoxy, zinc-rich, polyurethane stacks

Acrylic and hybrid chemistries for clean air permits

Epoxy and hybrid assembly bonding systems

Elastomeric, fire-retardant, and fillers

Cleaners, conversion coatings, maintenance kits

TDS Quick Download

Find data sheets instantly

Search by product, chemistry, or industry and jump to the portal.

Formulation Experts for Harsh Environments

LPTHC, LLC formulates protective coatings, water-based systems, specialty adhesives, and sealants that perform in the harshest infrastructure, OEM, and commercial environments—anchored by full TDS/SDS transparency and color-coded product swatches.

Why LPTHC

Corrosion, UV, chemical, and structural protection proven on bridges, pipelines, OEM assemblies, and commercial assets.

- Custom formulation and on-site technical support

- Full TDS/SDS library with application guides

- Audit-ready quality and compliance controls

Color-Coded Systems

Pantone-Style Formulation Cards for Specifiers

Each family carries a distinct swatch that appears on pails, literature, and TDS downloads—so procurement, applicators, and inspectors stay aligned.

Epoxy & Polyurethane

High-build epoxies, zinc-rich primers, and UV-stable polyurethane finishes engineered for severe-duty corrosion defense.

Acrylic & Hybrid Finishes

Fast-dry, odor-controlled formulations that keep OEM and commercial lines running while meeting strict air permits.

Assembly & Structural

Gap-filling epoxies and hybrids tuned for high-shear joints, dissimilar materials, and fast takt times.

Sealants & Fillers

Elastomeric and fire-retardant systems that maintain joint movement, aesthetics, and code compliance.

Surface Prep & Support

Cleaners, conversion coatings, and accessory products that lock in adhesion, cure, and lifecycle performance.

Product Lines

Color-Coded Systems for Precision Specification

A full portfolio spanning corrosion protection, low-VOC water-based finishes, structural bonding, and joint sealing—each line with clear, Pantone-like identification.

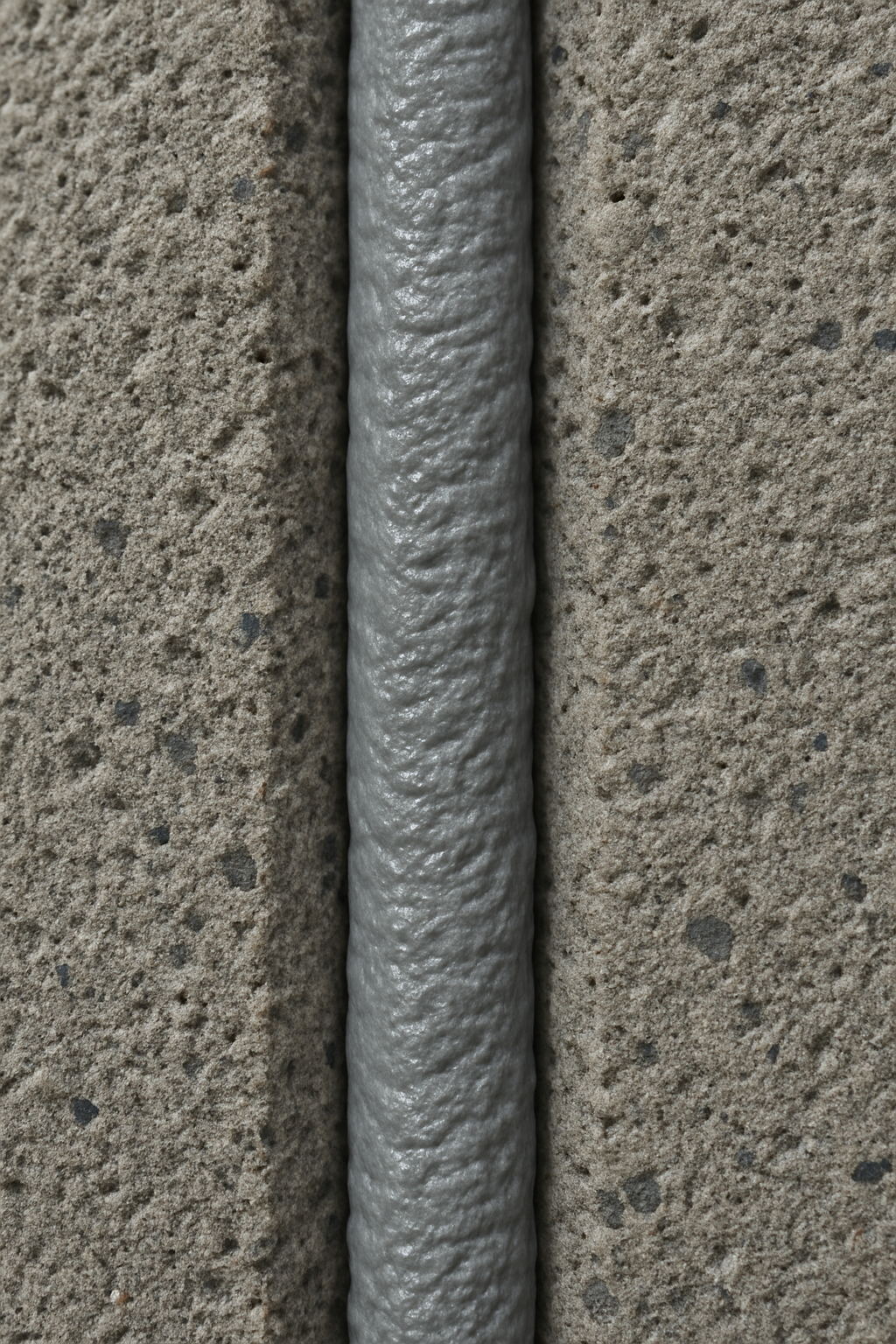

Epoxy & Polyurethane Systems

High-build epoxies, zinc-rich primers, and UV-stable polyurethanes engineered for steel and concrete under severe duty.

- ISO/NACE surface prep compatibility

- Salt fog & chemical immersion resistance

- Field-applied or shop-applied options

Low-VOC Industrial Finishes

Next-generation acrylic and hybrid chemistries delivering fast dry, odor control, and OEM line throughput.

- Meets stringent air permit thresholds

- High gloss retention and color stability

- Reduced cleanup and waste handling

Structural & Assembly Bonding

Epoxy and hybrid adhesives for high-shear joints, dissimilar materials, and high-speed production lines.

- Gap-filling and thixotropic options

- Room-temp or elevated-temp cure profiles

- Crash durability and fatigue tested

Joint Integrity & Finish Quality

Elastomeric sealants, fillers, and fire-retardant systems for façade, OEM enclosure, and industrial assemblies.

- Movement tolerance for dynamic joints

- Low shrink and smooth finishing

- Fire, smoke, and toxicity options

Surface Prep & Maintenance

Cleaners, conversion coatings, and accessory products that ensure adhesion, cure, and lifecycle performance.

- Surface conditioning and degreasing

- Non-chlorinated, worker-safe options

- Maintenance kits for field crews

Industry Selector

Choose Your Environment to See the Right System

Tab through the markets we serve—each panel shows the system stack, application guidance, and a direct path to the right TDS.

Application Pathways

Spec + TDSLong-Life Asset Protection

DOT-ready zinc/epoxy/PU stacks for bridges, pipelines, and water/wastewater assets—complete with inspection checkpoints.

- Salt fog, immersion, and QUV validation

- Rapid return-to-service cure windows

- Inspection packages with DFT, adhesion, gloss

Throughput Without Compromise

Process-safe chemistries for metals, plastics, and composites with predictable cure and cosmetic stability.

- Spray, roll, dip, and robotic application ready

- Color, gloss, DOI, and line speed alignment

- Adhesive and sealant options for assemblies

Low-VOC, High-Aesthetic Systems

Water-based and fire-retardant systems for façades, high-traffic floors, and interior finishes with clean air compliance.

- LEED-aligned VOC profiles and odor control

- Scratch, stain, and cleanability performance

- Color-matching with swatch validation

Co-Developed Chemistry

Joint development with your engineering teams for unique substrates, cure schedules, environmental, or sustainability targets.

- Lab-to-line scale-up and pilot runs

- Application engineering, training, and QA loops

- Dedicated technical point-of-contact

Technology & R&D

Formulation Science Backed by Applied Testing

Our Harwick innovation lab validates adhesion, corrosion, weathering, and mechanical properties against ASTM, ISO, and customer-specific standards.

Technical Programs

Co-development, rapid prototyping, and application engineering to ensure the chemistry and process align.

- On-site trials and applicator training

- Data packages with TDS/SDS alignment

- Continuous improvement loops with QA

Case Studies

Measured Results with ROI Transparency

Data-backed outcomes across infrastructure, OEM production, and commercial environments.

Bridge Rehabilitation

25-year design life | 38% maintenance cost reduction

Three-layer zinc/epoxy/urethane system restored steel bridges to DOT spec with accelerated curing for tight closures.

Read Case Study

OEM Finishing Efficiency

+18% line throughput | 22% VOC reduction

Water-based acrylic topcoat matched solvent-line appearance while reducing bake time and rework on metal assemblies.

Read Case Study

Commercial Façade Durability

40% gloss retention uplift | 2x cleanability

Low-VOC system delivered color-fast protection with stain resistance for premium retail and hospitality properties.

Read Case StudyTechnical Resources

Access TDS, SDS, and Application Guides

Centralized technical data with search, filters, and direct support from LPTHC engineers.

- TDS portal for coatings, adhesives, sealants

- SDS safety sheets and handling protocols

- Application guides for surface prep and cure